The Technology of Hiroshima

The Technology of Hiroshima

Industry in Hiroshima Prefecture is focused on monozukuri, manufacturing as a craft and art form. Manufacturing in this Prefecture consists of a deep, well-balanced mix, ranging from heavy industries such as shipbuilding, steelmaking and automaking to leading-edge industries such as production of electrical machinery and electronic components. For the past 11 years, Hiroshima Prefecture has topped the charts for the entire Chugoku/Shikoku/Kyushu region in terms of value of shipped manufactured goods.

The Prefecture’s manufacturing technology stands among the world’s best. In fields ranging from local industry to high-tech, the Prefecture’s companies include many that are one-of-a-kind, boasting unique, world-leading technologies, or that are No. 1 in national or global market share.

・Bichu & Bingo Japan Denim Project

・Kiru・Kezuru・Migaku technologies

・SADAKO

・YMR-II(Yamaha Motor Co., Ltd.)

・Pride of Hiroshima Exhibition

Return to list of exhibition themes

Holographic Display

(Asukanet Co., Ltd.)

ASKA3D-Plate is a special optical imaging panel made of glass or plastic. By imaging a display or object through the ASKA3D-Plate, a highly accurate real image can be displayed in mid-air. It can also be used as a holo touchless panel by combining sensors, and is increasingly in demand as a non-contact, hygienic interface.

- Click here for details(external website)

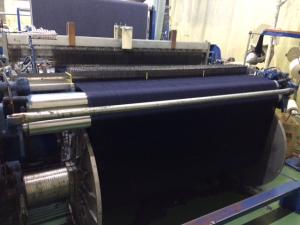

Bichu & Bingo Japan Denim Project

(Fukuyama City)

The regions located on the coast of the Seto Inland Sea from the western part of Okayama prefecture to the eastern part of Hiroshima prefecture, have flourished in cotton and Japanese indigo cultivation since the 1600s, and have prospered as one of Japan's leading textile producing regions.

In the 1960s, Japan began to import jeans in earnest. It attracted the younger generation, and the production of domestic denim accelerated. With this, our knowledge and technology related to the production of denim, such as spinning, dyeing, weaving, sewing, and processing, have gradually accumulated. The regions have currently grown to be Japan’s largest denim production area, with a more than 80% share of the domestic market.

Japan Denim continues to evolve in a uniquely Japanese way through its use of traditional textile production methods, indigo dyeing techniques, and our own original concepts producing a one-of-a-kind quality denim. Our denim products contribute to improving the brand value of famous fashion houses around the world and continue to be loved by many fans.

SPINGLE MOVE

(SPINGLE Co.,Ltd.)

Fuchu City is where our factory was born 90 years ago. SPINGLE MOVE is produced by craftsman. Significant features are that we produce rubber(outsole) and applying vulcanization method to leather(Upper). Since leather doesn’t have heat resistance, vulcanization + leather combination makes us one of a kind.

We are developing upcycling products to achieve sustainable development. Canvas sneaker SPM-1005R launched this spring is made from ORIGAMI CRANES. It is certificated by G7 summit.

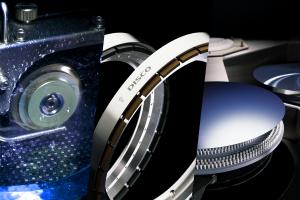

Kiru・Kezuru・Migaku technologies

(DISCO Corporation)

DISCO Corporation is a precision processing equipment and consumables manufacturer founded in Hiroshima Prefecture. DISCO specializes in “advanced Kiru, Kezuru, Migaku technologies,” used mainly in semiconductor manufacturing. Semiconductors are made smaller, thinner, and stronger through Kiru (dicing), Kezuru (grinding), and Migaku (polishing) technologies, respectively. These technologies contribute to smaller and higher performance smartphones and servers through miniaturized and more highly integrated die. In addition, thinning improves performance in power semiconductors, used in Evs and power plants, contributing to reduced carbon emissions through increased energy efficiency.

- Click here for details(external website)

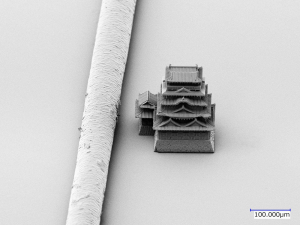

Micro 3D Printing Service

(CASTEM Co.,Ltd.)

The submicron 3D printing service enabled us to create a 0.2mm model of Fukuyama castle, on a scale of 1/170,000 of the actual castle. The service has been promoting collaborative research with the Kyoto University of Advanced Science on the “Nanoscribe” which is the world’s highest-accurate stereolithography 3D printing technology. It enables us to create products with shapes and precision that are impossible with conventional manufacturing methods by 3D modeling technology of three-layer two-photon polymerization and IP resin with submicron resolution.

There are some possibilities that we can create painless medical needles, tiny lenses that can film inside of blood vessels, and some parts of creatures by this service.

- Click here for details(external website)

SADAKO

(CASTEM Co.,Ltd.)

CASTEM Co., Ltd. has launched a project to preserve a paper crane folded by Ms. SASAKI Sadako, a victim of the atomic bombing, and deliver it to everyone around the world. By combining the latest digital technology such as 3D scanning and 3D printing with CASTEM's precision casting technology, the paper crane was revived as an eternal metal crane with Sadako's thoughts.

This project has been working with a mission of “Shape her wishes and thoughts which she put into her paper crane”, and a metal crane was created by precision casting technology based on the 3D data. We named the metal crane “SADAKO” and deliver it to people all over the world through our online store.

- Click here for details(external website)

- About paper crane in Hiroshima(external website)

YMR-II(YAMAHA MOTOR Co., Ltd.)

(HIROBO Limited)

HIROBO Co., Ltd. has many achievements as a pioneer of radio-controlled helicopters in the world.

HIROBO is a manufacturer of radio-controlled helicopters as well as a manufacturer with high resin molding technology.

HIROBO supports the manufacturing process of Japanese drones with its resin molding technology.

- Click here for details(external website)

Pride of Hiroshima Exhibition

(Pride of Hiroshima Exhibition Executive Committee)

[Exhibits] The exhibition will be divided into three zones: Postwar Recovery, Present, and Future. Each zone will display relevant objects and panels presenting the industry and perseverance of participating companies during each of these periods.

[Participating companies] Andersen Institute of Bread & Life, Izumi, Edion, Otafuku Sauce, Kumahira, Xyence, Satake, Daiso Industries, Daiwa Heavy Industry, The Chugoku Shimbun, The Chugoku Electric Power, RCC Broadcasting, Chudenko, Nishikawa Rubber, Nishikido, Hirogin Holdings, Hiroshima Aluminum Industry, Hiroshima Gas, Hiroshima Electric Railway, Hiroshima Toyo Carp, Hiroshima Mazda, Fukuya, Fujita, Fresta Holdings, Mazda, and Momiji Bank.

- Click here for details(external website)